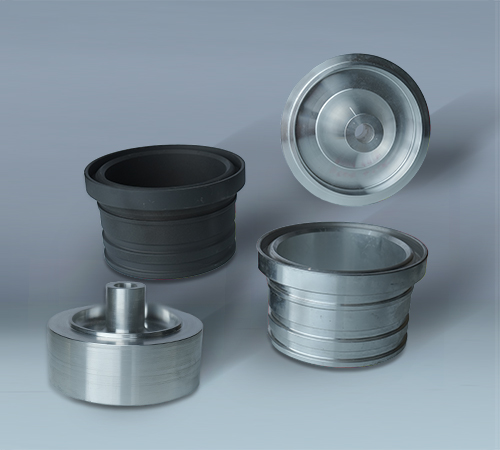

We specialize in precision CNC machining aluminum parts and components for use in an expansive range of industries.

Klintek Engineers is a name of trust in manufacturing accurate Aluminium Machined Parts. We are a certified Engineering company that offers different kinds of aluminum components and parts.

Aluminum machined components are essential parts used in various industries, including automotive, aerospace, electronics, and medical equipment manufacturing. These components are made from high-quality aluminum material that is strong, lightweight, and corrosion-resistant, making them ideal for use in a range of applications.

The machining process involves cutting, drilling, and shaping aluminum material to create precise and intricate parts. CNC machines are commonly used to achieve high accuracy and tight tolerances required for these components. Aluminum machining can also include surface finishing processes such as polishing, anodizing, and powder coating to provide additional protection and improve aesthetics.

Aluminum machined components can be customized to meet specific requirements and can be produced in large quantities or as single prototypes. They offer several benefits such as excellent strength-to-weight ratio, high durability, and low maintenance, making them a cost-effective solution for many applications.

At our company, we use the latest technology and advanced machinery to produce high-quality aluminum machined components. Our team of skilled professionals is dedicated to providing our clients with the best possible products and services to meet their needs.

Properties of Aluminum Machined Components

- Ductility and malleability: As a highly malleable metal, aluminum is easily machined and relatively easy to shape and drill.

- Versatility: There are a myriad of grades of aluminum and aluminum alloys, each designed with specific characteristics to meet differing needs.

- Resistances: Aluminum features a variety of excellent resistances to corrosion and most chemicals. When exposed to air, a thin, protective layer of oxidation forms on the surface of the metal, protecting it from further oxidation. Aluminum is also highly resistant to harsh chemicals, including most acids.

- Strength-to-weight ratio: Aluminum’s high strength-to-weight ratio makes it an ideal material for transportation applications. Aluminum alloys have the strength and durability needed for critical components, while the metal’s light weight reduces fuel consumption and emissions.

- Conductivity: Aluminum has excellent thermal and electrical conductivity properties. Aluminum is commonly used for major power transmission lines and is an excellent material for heat sink applications, such as computers, that require heat to be drained away rapidly. Aluminum is also a good reflector of heat and visible light, making it useful in lighting applications.

- Non-toxic: Aluminum is a non-toxic, odorless metal, which makes it popular for use in pharmaceutical and food production.