Piston Rings Manufacturing

Klintek Engineers offers Pistons made out of a variety of high-quality cast iron and steel materials. The extensive spectrum of materials ranges from grey cast iron, (heat treated) alloyed grey cast iron to spheroidal graphite cast iron. IP Rings, a sister concern of Klintek Engineers specializes in the manufacture of steel rings including high alloyed steel having 17% carbon content. Klintek Engineers offers Piston Rings with a wide range of surface treatments or coatings like Granoliting, Chrome plating, Chrome Moly, Molybdenum, Moly Chrome Ceramic, and flame-sprayed coatings.

The two critical dimensions required in rings are the Axial thickness (known as the width) and the size of the gap when the ring is closed to its working diameter.

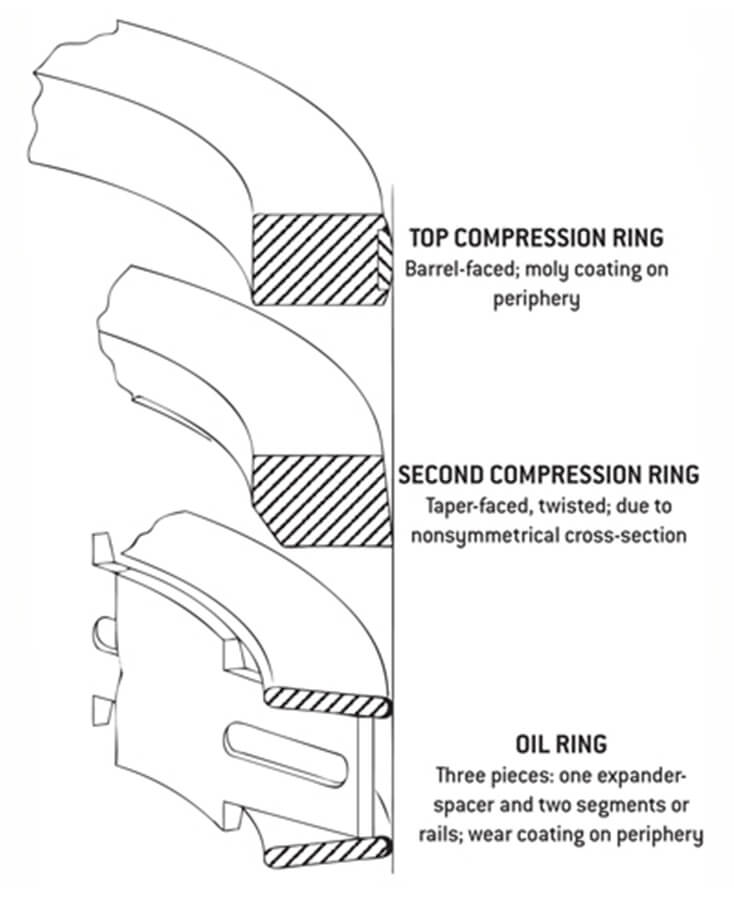

Top Compression Ring

Its primary function is to seal off combustion chamber and crankcase against each other. The compression rings are to prevent combustion gasses from getting into the crankcase from the combustion chamber.

Scraper rings

Scraper rings combine the function of the compression rings and the oil control rings, so in essence, they keep combustion gasses away from the crankcase and wipe off excess oil on the cylinder wall.

Oil Rings

The task of the oil control rings is to scrape off the excess oil from the cylinder wall to limit and to limit entry of the lubricating oil into the combustion chamber as much as possible. The aim is to achieve low oil consumption and sufficient lubrication of moving parts.

One of the key features that sets Klintek Engineers apart from the competition is our wide range of surface treatments and coatings.

We offer a variety of options to enhance the performance and durability of our piston rings, including:

- Granoliting: This surface treatment involves the application of fine glass beads under high pressure to the surface of the piston ring. This creates a smooth, even finish that improves the ring’s ability to seal and reduces friction.

- Chrome Plating: Chrome plating is a popular surface treatment for piston rings. It provides excellent wear resistance and corrosion resistance, making it ideal for use in harsh environments.

- Chrome Moly: This surface treatment involves the application of a layer of chrome and molybdenum to the surface of the piston ring. This improves the ring’s strength and durability, making it ideal for use in high-performance engines.

- Molybdenum: Molybdenum is a metallic element that is known for its excellent wear resistance and high-temperature strength. It is often used as a coating for piston rings to improve their performance in demanding applications.

- Moly Chrome Ceramic: This surface treatment involves the application of a layer of molybdenum and chrome ceramic to the surface of the piston ring. This improves the ring’s strength and wear resistance, making it ideal for use in high-performance engines.

- Flame Sprayed Coatings: This surface treatment involves the application of a layer of coating to the surface of the piston ring using a flame spray process. This improves the ring’s wear resistance and corrosion resistance, making it ideal for use in harsh environments.